Technical requirements for packaging paper and cardboard

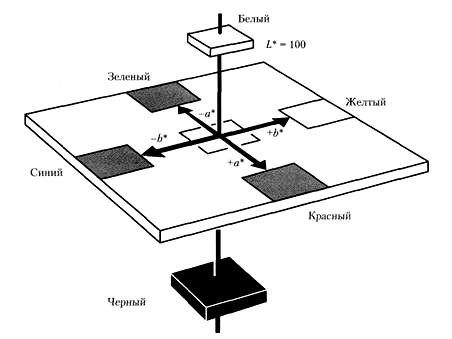

Rice. 1.18. CIELAB chromaticity coordinates

Many other examples of the whiteness or shade of packaging paper and paperboard could be given. Relatively easily defined whiteness/color can be achieved using a mineral pigment based coating, and perceived color can be altered using additional dyes and optical brighteners (also called fluorescent whiteners). The base color of a sheet of paper or cardboard, depending on its composition, affects the color of the coated surface. White with a bluish tinge is currently favored for retail packaging as this color is believed to give food products the best look, feeling fresh, clean and of high quality (in factory light conditions). retail).

There is another way to measure whiteness. Whiteness (iso) is the percentage of light reflected from a surface at a wavelength of 457 nm. The human eye perceives a wavelength range from less than 400 to more than 700 nm. Usually only the whiteness of the pulp is measured. Since this method measures the reflectivity of a surface at a single wavelength of blue light, it is of little concern to printers and packaging end users. Many grades of packaging paper and paperboard are brownish because they are produced without bleached fibers.

Surface smoothness

Surface smoothness is important from an aesthetic point of view and has an impact on print quality and gloss. With some printing technologies, paper with a rough surface does not accurately reproduce an image that is not printed, that is, the ink is not transferred from the printing plate to the surface of the material (for example, in gravure printing).

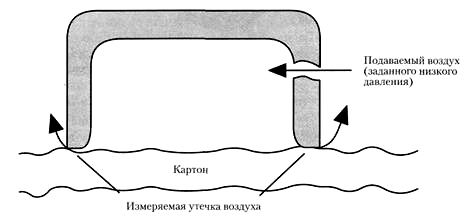

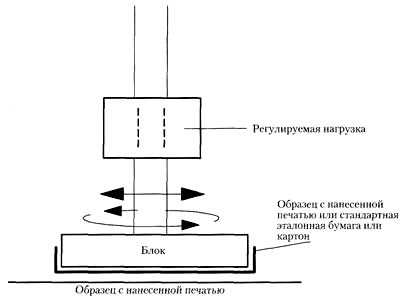

The smoothness of the surface as the degree of its roughness is measured by methods based on air leakage (Fig. 1.19) - the more rough the surface, the greater the rate of air leakage (at a certain pressure) from under the cylindrical edge of the knife blade placed on this surface. Therefore, the greater the surface roughness, the greater the amount of leakage. Since paper and cardboard are compressible materials, the pressure exerted by the knife blade can be adjusted.

Measuring the roughness at two given knife blade pressures also determines the compressibility of paper and board, which is important for printing. The most common methods for determining roughness and smoothness are based on the use of Parker PrintSurf (PPS) instruments from Bendtsen and Sheffield.

Rice. 1.19. Principle of surface roughness measurement

Surface structure

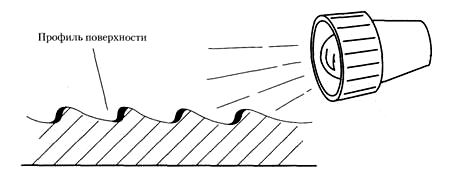

The structure of the surface is assessed visually under low angle illumination (Fig. 1.20), as a result of which any surface irregularities become visible. Surface evaluation results are dependent on lighting. The final surface structure is formed after calendering or laminating with a polymer film (or foil).

Gloss (gloss)

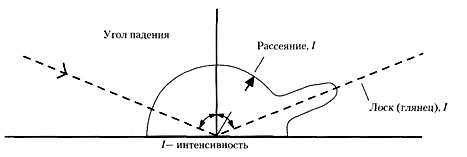

Gloss is defined as the percentage of light reflected from a surface at an angle equal to the angle of incidence. The gloss of paper and cardboard is measured at a reflection angle of 75 ° (Fig. 1.21), and the gloss of printed and varnished surfaces is measured at an angle of 60 °. Glossy (high gloss) surfaces are usually obtained by coating them with a coating followed by supercalendering or cast coating.

Rice. 1.20. Low Angle Illumination for Examining Surface Structure

To give a gloss to uncoated paper, it is processed on a polished cylinder with a polished surface.

High gloss paper is given by processing on a supercalender. The paper is passed through several gaps between alternately mounted hard metal and soft rolls of pressed fibrous material.

Rice. 1.21. The principle of measuring the gloss (gloss) of paper and cardboard

Opacity

Opacity refers to the ability of a sheet of paper or cardboard to obscure the print on the sheet below it or on the reverse side of that sheet. This property is particularly important in product packaging where paper is used as the outer wrapping of the printed surface. Opacity is measured with a spectrophotometer by comparing the reflection of light from the surface of one sheet placed on a black substrate with the reflection of light from a stack of 100 sheets.

Suitability for printing and post-processing

To provide the consumer with information (in the form of text and illustrations) and to improve the appearance of the package, it is usually printed on it. Lacquering is used to protect the applied print and give gloss. Surface color, graphic design, the presence of text, solid shading and halftone illustrations, as well as the presence or absence of gloss, significantly affect the appearance of the package.

Depending on the purpose of packaging, various graphic solutions are used, since packaging can be very different: from multilayer paper bags for cement to bags for SUGAR, labels for beer bottles, cardboard boxes for cereals or assorted sweets, chocolate or expensive cosmetics. The printing on the packaging of these products will also differ depending on the type of container - transport, group, individual, as well as depending on the characteristics of the labeling (for example, hazardous chemicals).

Currently, the packaging industry uses several printing processes - offset printing, flexography, letterpress, gravure, silkscreen and digital printing, which we will look at in more detail. All of them differ from each other in a number of important features that relate mainly to the composition of paint and varnish, methods of applying them to paper and cardboard base, as well as drying processes that make printing resistant and durable.

Despite the differences, printing processes also have common characteristics regarding printing properties and related to all types of paper and cardboard - these are the requirements for surface smoothness, its structure, the degree of gloss, opacity, surface strength, the degree of absorption of inks and varnishes by the surface , drying capabilities, abrasion resistance, surface and cut cleanliness. In some cases, the surface pH, surface tension and wettability also play a role.

The color of the applied print is measured with a spectrophotometer or densitometer (an instrument for measuring optical density). You can also compare colors visually under standard lighting using pre-set color references to ensure that package color is within standard tolerances under typical lighting conditions.

Surface strength

Appropriate surface strength is required to ensure good print quality and embossing. The offset printing process uses viscous inks that place high demands on surface strength at the separation point of the ink remaining on the sheet and the ink remaining on the blanket cylinder. The IGT "pluck and printability" test, which simulates the printing process, is used to evaluate surface strength . A special ink with a specific viscosity is applied to a test piece of paper or board at an increasing printing speed until a defect occurs - "plucking" fibers from the surface or the appearance of a bubble. Comparison of the parameters of the point of occurrence of a defect with the given characteristics allows predicting the probability of obtaining a satisfactory result.

Embossing is a method of creating a raised pattern or text on the surface of paper and cardboard. To achieve the desired result, high surface strength, interfiber strength and coating strength (if any) are required.

Another way to measure surface strength is to stick to the surface of several wax sticks with varying degrees of adhesion, due to the ability of the wax to adhere in molten form to the surface of the paper. The result is a value called the Dennison Plucking Resistance, the maximum number of wax stick that does not destroy the surface of the paper or cardboard when the stick is removed. The higher the stick number, the higher the surface strength. This test is only suitable for an uncoated surface, since if the latter is present, the molten wax fuses with the binder in the coating, subsequently giving an incorrect result. For an uncoated surface, this test is applicable to analyze both printable and adhesive properties of the surface.

When testing for adhesive properties, a stick is chosen as an indicator that “pulls” the fiber to a certain level, since if the strength is too high, the paper has insufficient adhesive properties with respect to water-based adhesives and hot melt adhesives, as well as when heat sealing blister packs with a backing from varnished cardboard with printing.

Absorption of printing ink and varnish. Drying

Paints contain a solvent (usually oil, an organic solvent, or water), a pigment or dye to impart color, and a resin to bind the pigment to the substrate. The composition of varnishes is similar except for the pigment or dye. The solvent, the choice of which depends on the type of ink and printing technology, is needed to transfer the ink from any container through the printing plate to the substrate. After printing, the solvent is removed by evaporation, absorption, or chemical solidification by oxidation or cross-linking by ultraviolet (UV) or electron radiation. Inks that are not yet completely dry when they exit the press (for example, conventional oil-based inks for lithography and letterpress printing) should be in their cured state - so

As with other properties, for the absorption of paints and varnishes the main thing is the uniformity of the structure. Uneven ink absorption can cause ink set-off, uneven printing, and ink bleeding on the back. To check the uniformity of absorption of printing ink by paper and board, as well as the degree to which they achieve the desired properties, tests are used based on measuring the degree of absorption of a standard ink or solvent.

In the standard offset printing process, the second color printed next to the first is transferred to a wetted substrate. Under certain circumstances, this can lead to the appearance of speckles ("marshmallow"), in connection with which a test was developed to test the repellency of paint on a surface wetted with water.

Surface pH value

For oil-based paints that dry by oxidation, a surface pH in the range of 6-8 is recommended. A surface with a pH value of 5 or less is undesirable, as it may impair the drying of some types of paints (eg oil lithographic). The test is carried out by measuring the pH value of a drop of distilled water transferred to the surface using a pH meter. The pH range is also important for papers and boards that are printed with metallic pigments (eg bronze) and papers that will be subsequently laminated with aluminum foil.

Surface tension

Knowing the surface tension is important when printing and gluing non-absorbent surfaces such as paper and cardboard with extrusion resin coatings. The polymer-coated surface is treated with a corona discharge to ensure high print quality. The result of such treatment can be measured by checking the surface tension with pens filled with special paints. It should be noted that the result of corona treatment decreases with time.

Abrasion resistance

Printing on paper bags should not be worn or smeared during transportation or when using bags. Wet abrasion resistance is needed when packaging materials become wet through contact with water or condensation, which often occurs with frozen or chilled food packaging. Good abrasion resistance is provided by a combination of paper and board surface properties, printing and varnishing technologies, as well as the composition of paints and varnishes. Abrasion resistance is measured relative to standards by standard test methods (Fig. 1.22).

Surface finish

The surface of paper and cardboard to be printed on must be free from fine particles and dust. Printing problems are associated with loose fibers, fiber fragments and tufts, the presence of non-fibrous particles and coating particles (see Figure 10.17 in Chapter 10). In addition, problems may arise due to finishing technologies (cutting and calendering); Difficulties can also arise during printing due to the presence of foreign particles that have entered the paper and cardboard during their production. In particular, specks (marbles) can appear in solid fills, resolution is lost in halftone illustrations, specks of ink appear in places where printing should not be, etc. All this leads to a decrease in print quality and the formation of additional waste.

There are no officially recognized methods for assessing the cleanliness of a sheet, although methods have been developed to assess the presence of free particles at the end of a roll or pack, and the presence of foreign particles on the sheet surface can be examined by rolling a soft polyurethane roller over it, and then counting the number of particles collected from a certain area under a microscope .

Rice. 1.22. Printing abrasion resistance test

If there are problems with foreign particles, the printer must detect them and determine the origin of the particles. Only by determining the nature of the particles can appropriate measures be taken to eliminate the source of the problem or minimize it. It should be taken into account that problems can be associated not only with paper or cardboard, but also with the printing press and areas adjacent to it, as well as with ink.

Read together with it:

- Rostov wholesaler Everest is merging with a loss-making meat supplier from Donetsk.Donskie Traditsii, a wholesale MEAT supplier operating in Donetsk since 2017, saw its revenue decline by 28% in 2024 , to 273.1 million rubles, while losses narrowed from 14.4 million rubles in 2023 to 5.3 million rubles. In contrast, Everest increased its revenue by 16% to 3.6 billion rubles in 2024, although net profit declined by 24%, to 11.9 million rubles. Creditors of Donskie Traditsii can f...

- Lawsuit against Tokarevskaya Poultry Farm: The claim is 40 million rubles.Information about the lawsuit became available through the arbitration case file, but the details of the claims have not yet been disclosed. Nika LLC, registered in September 2021 in Tambov, is engaged in the wholesale trade of grain and animal feed. In 2024 , the company recorded revenue of 125 million rubles and a net profit of 1.5 million rubles. As for the Tokarevskaya Poultry Farm, it was fou...

- Over the past three years, the Moscow region's agricultural machinery fleet has increased by nearly 2,500 units.Over the past three years, Moscow Region farmers have acquired approximately 2,500 units of new agricultural machinery. These include 390 tractors, 54 grain harvesters, 25 forage harvesters, and 2,000 other types of equipment. "To upgrade the technical infrastructure of our agricultural enterprises in the Moscow Region, we have created our own program: we reimburse a portion of the costs of purcha...

- Austria will approve sanctions against Russia, which it delayed due to Raiffeisen.Austria has announced its support for the sanctions package against RUSSIA. it previously demanded that sanctions against Rasperia be lifted in order to compensate Raiffeisen Bank International for the €2 billion it was forced to pay by a Russian COURT ruling.Austria has decided not to block the adoption of a new package of EU sanctions against Russia, although it had previously made demands regar...

- While Argentina is still waiting, Bolivia has already received the green light to export beef offal to China.Both sides confirm that the ongoing negotiations are proceeding as planned, and recent reports indicate that news could be released by the end of this month. However, others are more skeptical, claiming that the negotiations are being delayed amid anti-China dalliances between President Javier Milei and his American counterpart, Donald Trump. Meanwhile, some are already celebrating the opening of ...

- Парагвай пользуется тарифами Трампа и увеличивает экспорт мяса в СШАС 25 августа бразильская говядина на рынке США облагается пошлинами в размере 76,4%, что нарушило торговые потоки во всем регионе. Однако Парагвай воспользовался этой ситуацией, чтобы увеличить объёмы продаж своего красного мяса в США. Парагвай был одной из стран, выигравших от политики администрации Трампа, которая ввела сниженные тарифные ставки примерно на 1......

- Russian Meat Smuggling: Kazakhstani Processors Report Market ProblemsAzamat Shalmagambetov, HEAD of a MEAT processing company, noted that Russians are importing beef and horse meat, especially to the northern regions and Astana. This offers consumers an advantage due to low prices, but behind it lies a smuggling scheme that allows them to evade tax obligations. According to Shalmagambetov, a veterinary EXPORT certificate is issued at the border for crossing, after ...

- In the Dubrovensky district, a woman was deprived of parental rights for the third time due to alcohol abuse.October 13,Vitebsk . The Dubrovensky District Prosecutor's Office filed a lawsuit to terminate parental rights for a seven-month-old girl belonging to a woman who abuses ALCOHOL and leads a dissolute lifestyle, BelTA learned from the Vitebsk Region Prosecutor's Office. The decision was prompted by the results of extensive work with the family. In March of this year, the Commission on Minors' Affai...

- A drunk taxi driver was detained in Vitebsk.October 12, MINSK . A drunk taxi driver with a blood ALCOHOL level of over two ppm was detained in Vitebsk, the Ministry of Internal Affairs press service told BelTA. In the morning, a Vitebsk traffic police crew noticed a Volkswagen that was clearly speeding along the central avenue. Officers signaled the driver to stop, which he ignored, and a pursuit ensued. The driver ignored repeated requests...

- RBI asked for sanctions relief against Rasperia to unblock Strabag sharesRasperia has been under sanctions since 2024. If the sanctions are lifted, RBI will receive Rasperia's stake in Strabag. A Russian COURT previously ordered RBI's subsidiary to pay $2 billion in damages.Raiffeisen Bank International (RBI) has asked the European Union to lift sanctions against Rasperia Trading, reportsBLOOMBERG, citing RBI HEAD Johan Strobl. If the EU makes such a decision, Raiffeis...