The Ural meat-packing plant "Sibagro" is certified according to ISO 22000:2018.

According to Deputy Director of Quality, Daria Khudorozhkova, preparations for the independent expert inspection lasted about a year. During this time, all documentation for equipment, technical, and technological processes was standardized and updated. A large team of professionals participated in the work, including employees from the quality management and production control departments, the veterinary service, a sanitary inspector , and a disinfector.

Ultimately, the auditors highly praised the effectiveness of the multi-stage quality and safety management system across the entire production chain: from incoming raw material inspection to veterinary and sanitary inspection upon shipment of finished products, particularly noting the level of professional competence of the staff.

In 2018, the Khoroshy Vkus food processing plant became part of the Sibagro holding company. The company now boasts state-of-the-art laboratory equipment and the only FoodSkan express analyzer in the Sverdlovsk region. Laboratory staff determine the physicochemical properties of products, such as protein, fat, salt, and moisture content.

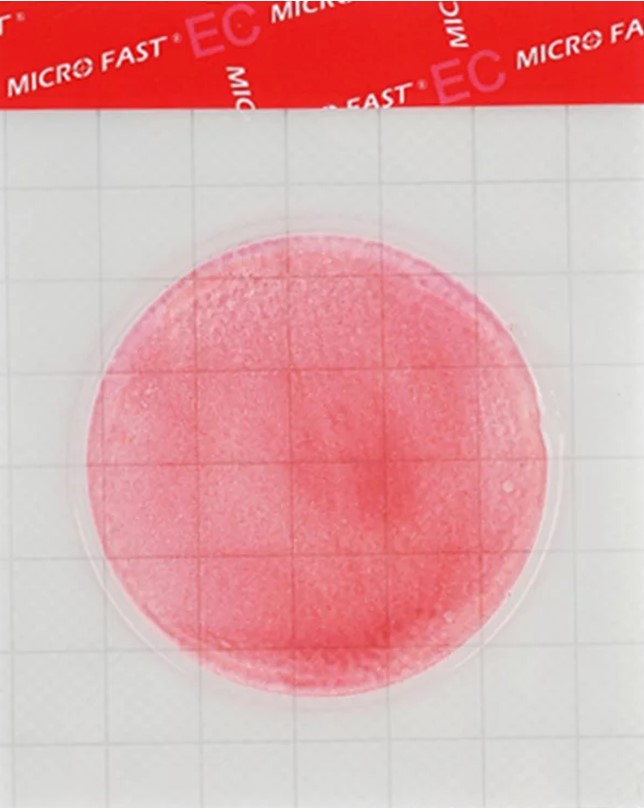

"For example, for chilled pork, we have seven checklists with a variety of criteria, from visual assessment of carcasses to pH and temperature measurements," explains Darya Khudorozhkova. Samples from each batch undergo mandatory microbiological testing . Furthermore, each product type is sent monthly for testing to independent laboratories.

Certification audit for compliance with system requirementsISO 22000:2018 was the first in the company's history, and preparations have already begun for the next one, which will take place in three years.

Read together with it:

- The first robotic warehouse using domestic equipment was launched in the Chuvash Republic's agricultural sector.At the end of 2025 , the Vurnary Meat Processing Plant commissioned the first domestically produced robotic warehouse for finished goods. The entire system, from hardware to software, was developed and manufactured in Russia. To implement the import substitution program and achieve the goals of the national project "Technological Support for Food Security," 3......

- Нарушения микробиологических стандартов выявлены в мясных полуфабрикатах Приморского производителяПроведенные 21 января текущего года исследования показали, что в пельменях и варениках с картофелем обнаружены бактерии группы кишечной палочки, а уровень бактериальной обсемененности превысил нормативные значения в 4-5 раз. Данные тесты стали частью производственно-лабораторного контроля. Результаты были занесены в автоматизированную систему «Веста» и доведены до сведения заказчика. Примечательно...