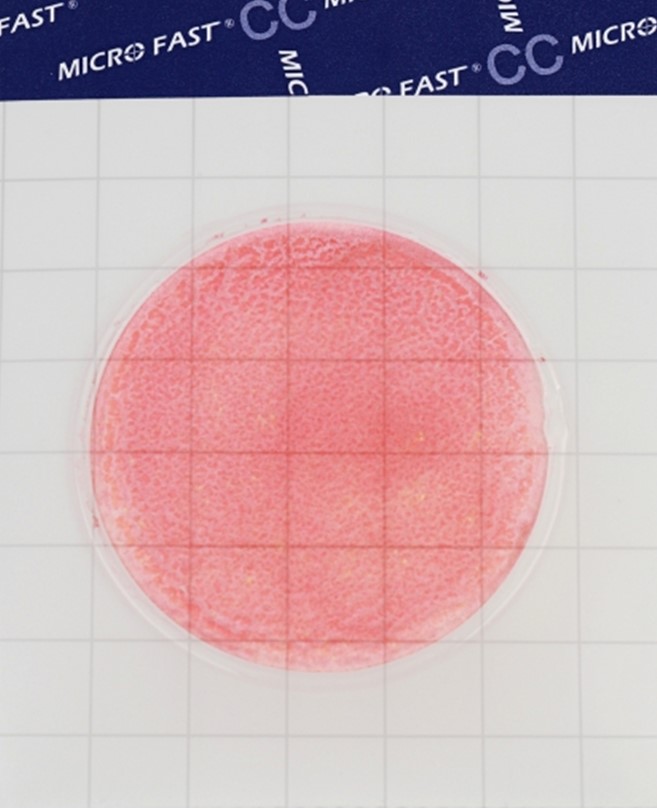

Having mastered the production of multi-colored tiles, the plant in Mikashevichi became the leader in the region in terms of wage levels

Photo is illustrative in nature. From open sources.

The lure of big city lights to young people from villages, towns, and regional centers is understandable, understandable, and even positive. After all, a metropolis offers more opportunities to realize one's potential and talents, numerous prospects for furthering one's education, and finding not only a place in the national economy but sometimes even a reliable life partner.

In these migration processes, something else is more important: a firm decision to return to one's small homeland with accumulated experience and knowledge. This is precisely what unites most of the young people we met during our business trip to the Luninets District.

And judging by the fact that construction is beginning on a new microdistrict of 17 high-rise buildings along Chapayeva Street in the district center, these encounters are clearly no coincidence: the region has everything one needs to earn a decent living, build a career, start a family, and raise children. Now we'll try to prove it.

Architects will be delighted

. In 2024 , on its 40th anniversary, Spetszhelezobeton OJSC completed a large-scale investment project. With the participation of industry leaders from the Brest Region and the Luninets District, and the traditional ribbon-cutting ceremony, the second production line for vibro-pressed curbs, blocks, and paving slabs, including multicolored color-mix, was launched.

Built in the 1980s to produce 60,000 cubic meters of reinforced concrete pipes annually, the facility has not only significantly expanded its product range—diameters range from 300 to 3600 mm—but also launched the production of railroad ties, turnout beams, and landscaping elements, doubling its capacity.

Approximately 60% of its products are exported , primarily to the Russian Federation. This refutes the common misconception that exporting concrete products over distances greater than 150 km is economically unviable, as it results in a loss of profitability. Last year, reinforced concrete sleepers, beams, and pipes with diameters from 1.2 to 2 meters, including the recently introduced microtunnel pipes, became top sellers outside the country, sometimes with delivery distances of up to 5,000 kilometers. These pipes allow for the installation of pipelines and utility lines underground without damaging the landscape. Quality and precise order fulfillment are the joint-stock company's main strengths.

The decision to implement a second vibration pressing line, according to Tatyana Gavrilovich, Deputy Director of Production at Spetszhelezobeton OJSC, was a natural consequence of life:

"We couldn't fulfill orders. In the summer, we had to produce paving slabs around the clock, using equipment that was far from new—we've been producing landscaping elements since 2002."

As a result, a year ago, the "old" line was re-equipped with a backup unit. Essentially, it's a mini-factory. While the previous German line lacked a concrete mixing unit, the new Chinese one can be installed practically anywhere, provided there's access to electricity. All that's left to do is transport raw materials—cement, sand, and pigments.

The project cost 8.5 million rubles, and the workforce increased from 350 to 375. Interestingly, the new equipment is maintained by the youngest team in the plant, with an average age of 28. Foreman Ruslan Kiptsevich isn't even 24 yet. A young specialist with a degree from Brest State Technical University, he arrived here last year on assignment. He basically finished his studies and returned home. Originally from the agrotown of Vulka-2, he's now a city dweller, settling in Mikashevichi, closer to his workplace.

Although, as he admits, he goes almost every weekend to help his parents and grandmother manage their vegetable gardens, including their 100-acre strawberry plot.

Strawberries are the queen of the local fields and garden plots. The art of cultivating them in the Luninets region is thriving, perfecting, and being passed down to new generations, making the local village of Dvorets the strawberry capital of the country – home to the largest seasonal wholesale strawberry market , capable of handling up to 150 trucks at a time. Last year, Dvorets set a record turnover – at the peak of the harvest, they sold an average of 438 tons of strawberries per day. This year's results, due to spring frosts, are more modest – around 290 tons per day. Still, it's not a small amount.

…Meanwhile, from the company's administrative office, we head to the reinforcement molding shop to meet the unique youth team, along with its manager, Ivan Zenevich. Incidentally, after working for a while in Lida after graduating, he also returned to his hometown, to the plant where his mother and brother had worked. A fateful meeting awaited Ivan there, with his future wife, a sports enthusiast like himself—she competes for the company in volleyball, football, and basketball.

"I specifically selected talented young guys for the new line," our interlocutor comments on the events that took place a year ago. "There was only one criterion: that their eyes sparkled, that they came to work not to waste time, but with joy and inspiration, and that they returned home proud of a day well spent. Basically, we were a team. And it worked! So, meet our jack of all trades..."

The shop foreman introduces Alexander Klevtsevich, the control panel operator of the new Hercules automated production line, and allows him to take a few minutes off from his work.

Our new acquaintance arrived at the plant in January 2023, and by September he was already finding common ground with a group of representatives from a Chinese equipment supplier—using Google Translate and sign language. This smart young man was assigned to assemble the machinery arriving at the plant. Alexander, an electrician by trade, grew up in Pinsk and graduated from the Industrial Pedagogical College in his hometown. But fate brought him to Mikashevichi, via… Minsk , where he worked for a construction company. He might have remained in the capital if not for a chance meeting on the train. After a weekend spent with her parents in Mikashevichi, the pleasant woman was returning to work at a prestigious restaurant in the capital, where she had started after graduating from a specialized college in Minsk.

"A few hours on the road flew by, and a year later we got married and moved to my wife's hometown," Alexander recalls. "So, I've been a resident of Mikashevichi since 2013. We have two beautiful daughters, and we own our own place—I saved up for an apartment by building a cottage for a wealthy and meticulous Minsk resident for several years. That's also when I learned a lot of technical know-how. Now it's really helpful at work."

Alexander emphasizes that he's come to the company for the long haul because he wants to see his wonderful girls grow up (this was practically impossible when he was working shifts in Minsk for work), and he's ready to improve and grow professionally:

"We're looking forward to welcoming our Chinese friends again—we're starting to develop a new form of paving slabs and the supply of multi-colored concrete, and we'll conquer promising markets!"

Paving slabs from Mikashevichi already adorn the squares of Brest, Luninets, Pinsk, Soligorsk, Mozyr, and other towns across the country, and are gaining popularity in other Russian regions as well. Last year, over 47,000 square meters of space were dedicated to transforming the city for the regional "Dazhynki" festival and fair for rural workers. This year, vibrant, colorful produce was shipped to Beloozersk in the Berezovsky District, which has taken over the baton for hosting the main grain harvest festival.

On the banks of the milk river , the Luninetsky Dairy Plant (OAO)

is embarking on a large-scale business plan, "Construction of a Dry Dairy Products Plant," which has received 70 million rubles in credit alone. The company intends to increase its processing capacity from 300 to 500 tons per day. Essentially, a new plant will be built, and to accommodate it, they even had to squeeze out their neighbors—Luninetsky District Agroservice shared a plot of land. On the way to the plant, Pavel Vabishchevich, Deputy Chairman of the Luninets District Executive Committee for Economics, briefed the participants on the project:

Approximately 52% of sales revenue in the district comes from industry. The agricultural sector is represented by 12 agricultural enterprises and 81 farms. These range from small farms with 3-5 hectares of land to large farms with holdings spanning thousands of hectares. The average milk yield per cow is approaching 7,500 kg per year, or more than 300 tons of milk per day. And herd productivity continues to grow—according to the plan for the next five years, at a rate of up to 7% per year.

For example, the Novitskikh farm at its unitary enterprise, Mezhleskoye, already yields 10,000 kg per cow—the highest yield in the district. So, in a few years, it's entirely possible to increase daily milk yield to 400 tons or more. Selling valuable raw materials, including for export, is considered short-sighted, which is why the local dairy has begun a comprehensive overhaul of its drying equipment. The company hopes not only to increase its milk powder production volumes but also to expand its product range.

"The maximum we were able to process this year was 330 tons of raw material per day. That's the ceiling. Furthermore, our two dryers, each with a capacity of 500 kg of evaporated moisture, are quite old and worn out. Renovation was absolutely necessary. A Slovak company won the tender for a drying complex with a capacity of 1,500 kg of evaporated moisture. A designer has also been selected. In addition to increasing volumes, we will be able to produce higher-quality products and new types—this could include whole milk powder and instant milk powder ," the conversation continues in the office of Nikolai Bokhonyuk, the director of the joint-stock company. "We expect to receive our first products in a year and a half, and we will continue to expand production, including whole milk products.

" About 60% of the output of Luninetsky Dairy Plant OJSC is exported—to Russia, Azerbaijan , Uzbekistan , Kazakhstan , Georgia, and Armenia.

The joint-stock company, which at one time acquired two agricultural enterprises, also contributes to milk production . And not only through high milk yields.

"Our specialty is hypoallergenic A2 milk, which we obtain from specially selected cows with two copies of the A2 gene in their DNA. It does not contain A1 betacasein, is as close in composition to human breast milk as possible, and is better digested, especially by young children and the elderly," explains Chief Technologist Natalia Bobkovich. "The introduction of the A2 product line was preceded by extensive and painstaking research. "At our agricultural unitary enterprise, Agro Lobchanskoye, a genetic analysis of the dairy herd was conducted by an independent accredited laboratory, selecting cows with the A2A2 genotype. They are housed and milked separately. Selection continues, including at our second agricultural enterprise, OJSC Sinkevichsky, as well as at one of the district's farms. We produce up to 10 tons of A2 milk per day and supply it to retailers as a premium product in glass bottles under the Asablivae brand. We also use it to make sour cream, butter , cottage cheese , and bio-yogurts with a variety of fillings. Incidentally, our yogurts received three first-place diplomas in the Healthy Nutrition category at the BELAGRO-2024 exhibition.

Natalia's path to the joint-stock company led through Mogilev, where she earned two degrees in technology and economics at the University of Food Science, and Minsk, where, after completing her required two years of work placement at a dairy plant, she followed her husband, radically switching from food production to banking. But in 2019, the family returned to their homeland. Natalia returned to the plant again – because, as the director claims , she is a "God-given technologist."

Alexander Rebkovets, appointed chief engineer six months ago, is equally involved in the new project. His team will be responsible for the project's approval and equipment installation. A plus is that he knows a working dryer inside and out – he began his career at the dairy plant, practically straight out of school: he worked as a mechanic during his internship at the Pinsk State Agrarian Technological College and then spent several more years working placements. Alexander lured his wife, Olga, from Brest to Luninets. He met her during his first year of college and soon discovered that they were both born on November 17, 1984.

"I'm 12 hours older," Alexander smiles, having since become very skeptical of the veracity of horoscopes. "We're not very similar in personality. But somehow we learned to overcome difficulties. We even built a house ourselves, between picnics on the property."

Like many (in fact, the vast majority of families in the Luninets region), the Rebkovtsys' hobby is growing strawberries on their plots of land in the village. The income from hard labor on the land in their spare time is a good supplement to their salary. But now, says Alexander, there's hardly enough time for that—all his attention is on the new production project, on which the future of the company depends.

24 years on the runway

On the day of our arrival in the Luninets district, near its border with Soligorsk, an important event was taking place at the Novitskikh farm. Incidentally, this is the same farm where they milk 10 tons per cow annually, providing a reliable raw material base, including for the local dairy plant. A second automated vegetable blast freezing line with a capacity of 10 tons per hour was being commissioned, marking the completion of a two-year, €7 million project. Of course, we couldn't miss it.

Especially since this farm doesn't fit the usual clichés. It's simply gigantic. Judge for yourself. They lease 9,000 hectares of land. They employ more workers than any of the other farms we visited – around 500, including the acquired Mezhleskoye UP, which hasn't changed its specialization and continues to farm livestock, raising 4,000 cows.

In workshops spread over 10 hectares, potatoes , carrots , and beets are washed and packaged in special breathable packaging or, if necessary, chopped and frozen. A deep-freeze plant for vegetables and berries has been built using state-of-the-art freon-free equipment.

The farm was one of the first in the country to begin packaging washed vegetables 12 years ago. To effectively preserve fresh vegetables during the off-season, it uses state-of-the-art storage facilities with a capacity of 80,000 tons.

Add to this 55 of its own trucks, equipped with temperature recorders and loggers to monitor temperature and humidity en route, ready to deliver vegetables anywhere in the country within 48 hours for orders of 20 tons or more. And not only that.

Last year, 100,000 tons, or 90% of the harvest, was exported. This year, these figures are expected to increase. Because they grew 6.5 times more carrots than the entire country allocates to stabilization funds during the off-season, and if necessary, they could fill the entire country's granaries with potatoes. The main export market is Russia . They export carrots, potatoes, and beets there, which have been grown for the past five years using a new and effective precision farming technology.

Vladimir Novitsky, born in the Luninets region to a large family, started the business 24 years ago with an old tractor and 50 hectares of rented land. His father worked as a driver, his mother as a field worker. And his son took up growing carrots on the site of a former runway, from which crop duster planes once took off to spread fertilizer on the fields. Vladimir Konstantinovich's business took off brilliantly. Today, many of the head of the farm's relatives are involved in the production process, and his children , including the youngest, also help out.

"Everything in our team is built on trust and personal example. How else could it be?" the owner greets us with a smile and gives us a personal tour of the enormous workshop where vegetable production is in full swing, as well as the storage facilities where it's easy to get lost without a guide. "This year's potato harvest is good, and the carrot harvest is simply excellent: we harvested 300 and 800 centners per hectare, respectively. We primarily fulfill retail orders. We sell potatoes domestically for 68 kopecks per kg, and a little more expensive abroad – 80 kopecks. Stabilization funds have been fully formed.

The head of the farm is confident that there will definitely be plenty of vegetables in the country."

In numbers:

According to Belstat, the contribution of agricultural production to Belarus's GDP in 2024 exceeded 6%. Per capita, the country produces 913 kg of grain, 958 kg of milk, 41 kg of potatoes, and 304 kg of vegetables. Agricultural organizations account for 78.9% of output, peasant farms account for 2.9%, and the remaining 18.2% is grown on private plots.

Protecting the Lives of Rescuers:

The unique Republican Production Unitary Enterprise "Uniform," part of the Bellegprom concern, will celebrate its 25th anniversary next year. Uniform develops, manufactures, and mass-produces firefighting gear, including special protection against extreme heat—it can withstand temperatures up to 600 degrees Celsius. And not only that. We mistook the suit worn by rescuers who deal with stinging insects, usually hornet infestations, for beekeeper gear. We were surprised to learn that a hornet flying at up to 15 meters per second can easily knock a person off their feet.

"We are the main supplier of protective suits, gloves, gauntlets, and helmets for the Ministry of Emergency Situations. We produce clothing with special protective properties that meet international regulations," says Director Irina Senyuk, greeting us in an office adorned with certificates of appreciation from the Ministry of Emergency Situations. "There is demand for our products not only domestically but also internationally."

To confirm the director's words, we notice Arabic script on the protective jackets being sewn in the workshop. Irina Nikolaevna, noticing the surprised looks, immediately comments:

"We are currently making suits for rescuers from Libya. A delegation from there visited us this summer and learned about the production process. We ordered 60 sets of suits with helmets and gloves for competitions—this is a joint project with our Ministry of Emergency Situations. The entire contract is for 400 sets. We use a rubberized material, and the suits, helmets, and gloves are the same as those worn by our rescuers." All materials are domestically produced, with the exception of reflective hot-melt tape.

Uniform exports 11% of its output, but only because it can't fulfill domestic orders due to insufficient production capacity. "

We're planning to expand. We expect to double production volumes by 2028. We'll be building a 32-person workshop in Luninets, primarily for seamstresses. Our Mikashevichi facility will remain the developer and holder of all documentation and certificates. We conduct compliance testing at the Fire Safety Research Institute and the Vitebsk Scientific and Practical Center of the Ministry of Emergency Situations, and we closely collaborate with the Republican Emergency Management and Response Center of the Ministry of Emergency Situations on material properties," the company's director continued, demonstrating the latest product. "

Yes, don't be surprised—rescue suit designs are also constantly being improved and changed." For example, today, the Ministry of Emergency Situations (MES) staff consider a more convenient option: a separate jacket and coverall, all secured with metal latches. This works well in extreme situations, for example, if a tank is on fire and there's a risk of an explosion and a blaze, a firefighter who enters and contains it will be easier to evacuate via a hitch.

"Even though everyone thinks it's a cosmonaut suit," the interviewee smiles. "The suit can withstand temperatures of 600 degrees Celsius, the metallized coating is Chinese, and the fiberglass is domestic. The materials are combined in Vitebsk, bonded with a special fire-resistant adhesive. The helmets are also manufactured using molds developed as part of a joint research project with the Research Institute of Fire Safety and Emergencies of the Ministry of Emergency Situations. All rights reserved. We do the assembly, interior fittings, and testing ourselves.

We're considering another version of the "cosmonaut suit," which turns out to be an export version—designed for Russian firefighters and certified according to the GOST standards of the Union State. Incidentally, Russians prefer overalls without a separate jacket.

The construction of a new workshop in Luninets is intended to expand supplies to Russia. Additional jobs will be created for residents of the region, and we'll bid farewell on this positive note, but we'll return to see how these plans come to fruition. It's important that they continue to stimulate the forward movement that continues in the Luninets region. It's proven.

From the horse's mouth

, Alexander Savin, Chairman of the Luninets District Executive Committee,

says , "Our district is industrial and agricultural. The main industrial giant is RUPP Granit, with a processing capacity of 300 tons of crushed stone per hour and a share of up to 50% of industrial output, employing 2,106 people."

Small businesses are also completing the five-year plan with flying colors, demonstrating growth of 1.3-1.5 times. These include the dairy plant, recognized as the best in the district last year, Spetszhelezobeton, and Viktoria, the only manufacturer of cast aluminum cookware with a non-stick coating in the country, producing up to 100,000 frying pans per month. The husband and wife team started the business , figuratively speaking, in their garage. Today, they employ 238 people. Their products are in demand both domestically and internationally.

All our agricultural enterprises are profitable, and the number of farmers is growing every year due to the consolidation of their private plots. However, land is not as scarce here as in other districts. Farmland located near the M10 highway has long been taken up. Farmsteads within a 20-30-kilometer radius are not cheap. Large farmers primarily cultivate vegetables, while smaller ones focus on strawberries, blueberries, and raspberries.

In these migration processes, something else is more important: a firm decision to return to one's small homeland with accumulated experience and knowledge. This is precisely what unites most of the young people we met during our business trip to the Luninets District.

And judging by the fact that construction is beginning on a new microdistrict of 17 high-rise buildings along Chapayeva Street in the district center, these encounters are clearly no coincidence: the region has everything one needs to earn a decent living, build a career, start a family, and raise children. Now we'll try to prove it.

Architects will be delighted

. In 2024 , on its 40th anniversary, Spetszhelezobeton OJSC completed a large-scale investment project. With the participation of industry leaders from the Brest Region and the Luninets District, and the traditional ribbon-cutting ceremony, the second production line for vibro-pressed curbs, blocks, and paving slabs, including multicolored color-mix, was launched.

Built in the 1980s to produce 60,000 cubic meters of reinforced concrete pipes annually, the facility has not only significantly expanded its product range—diameters range from 300 to 3600 mm—but also launched the production of railroad ties, turnout beams, and landscaping elements, doubling its capacity.

Approximately 60% of its products are exported , primarily to the Russian Federation. This refutes the common misconception that exporting concrete products over distances greater than 150 km is economically unviable, as it results in a loss of profitability. Last year, reinforced concrete sleepers, beams, and pipes with diameters from 1.2 to 2 meters, including the recently introduced microtunnel pipes, became top sellers outside the country, sometimes with delivery distances of up to 5,000 kilometers. These pipes allow for the installation of pipelines and utility lines underground without damaging the landscape. Quality and precise order fulfillment are the joint-stock company's main strengths.

The decision to implement a second vibration pressing line, according to Tatyana Gavrilovich, Deputy Director of Production at Spetszhelezobeton OJSC, was a natural consequence of life:

"We couldn't fulfill orders. In the summer, we had to produce paving slabs around the clock, using equipment that was far from new—we've been producing landscaping elements since 2002."

As a result, a year ago, the "old" line was re-equipped with a backup unit. Essentially, it's a mini-factory. While the previous German line lacked a concrete mixing unit, the new Chinese one can be installed practically anywhere, provided there's access to electricity. All that's left to do is transport raw materials—cement, sand, and pigments.

The project cost 8.5 million rubles, and the workforce increased from 350 to 375. Interestingly, the new equipment is maintained by the youngest team in the plant, with an average age of 28. Foreman Ruslan Kiptsevich isn't even 24 yet. A young specialist with a degree from Brest State Technical University, he arrived here last year on assignment. He basically finished his studies and returned home. Originally from the agrotown of Vulka-2, he's now a city dweller, settling in Mikashevichi, closer to his workplace.

Although, as he admits, he goes almost every weekend to help his parents and grandmother manage their vegetable gardens, including their 100-acre strawberry plot.

Strawberries are the queen of the local fields and garden plots. The art of cultivating them in the Luninets region is thriving, perfecting, and being passed down to new generations, making the local village of Dvorets the strawberry capital of the country – home to the largest seasonal wholesale strawberry market , capable of handling up to 150 trucks at a time. Last year, Dvorets set a record turnover – at the peak of the harvest, they sold an average of 438 tons of strawberries per day. This year's results, due to spring frosts, are more modest – around 290 tons per day. Still, it's not a small amount.

…Meanwhile, from the company's administrative office, we head to the reinforcement molding shop to meet the unique youth team, along with its manager, Ivan Zenevich. Incidentally, after working for a while in Lida after graduating, he also returned to his hometown, to the plant where his mother and brother had worked. A fateful meeting awaited Ivan there, with his future wife, a sports enthusiast like himself—she competes for the company in volleyball, football, and basketball.

"I specifically selected talented young guys for the new line," our interlocutor comments on the events that took place a year ago. "There was only one criterion: that their eyes sparkled, that they came to work not to waste time, but with joy and inspiration, and that they returned home proud of a day well spent. Basically, we were a team. And it worked! So, meet our jack of all trades..."

The shop foreman introduces Alexander Klevtsevich, the control panel operator of the new Hercules automated production line, and allows him to take a few minutes off from his work.

Our new acquaintance arrived at the plant in January 2023, and by September he was already finding common ground with a group of representatives from a Chinese equipment supplier—using Google Translate and sign language. This smart young man was assigned to assemble the machinery arriving at the plant. Alexander, an electrician by trade, grew up in Pinsk and graduated from the Industrial Pedagogical College in his hometown. But fate brought him to Mikashevichi, via… Minsk , where he worked for a construction company. He might have remained in the capital if not for a chance meeting on the train. After a weekend spent with her parents in Mikashevichi, the pleasant woman was returning to work at a prestigious restaurant in the capital, where she had started after graduating from a specialized college in Minsk.

"A few hours on the road flew by, and a year later we got married and moved to my wife's hometown," Alexander recalls. "So, I've been a resident of Mikashevichi since 2013. We have two beautiful daughters, and we own our own place—I saved up for an apartment by building a cottage for a wealthy and meticulous Minsk resident for several years. That's also when I learned a lot of technical know-how. Now it's really helpful at work."

Alexander emphasizes that he's come to the company for the long haul because he wants to see his wonderful girls grow up (this was practically impossible when he was working shifts in Minsk for work), and he's ready to improve and grow professionally:

"We're looking forward to welcoming our Chinese friends again—we're starting to develop a new form of paving slabs and the supply of multi-colored concrete, and we'll conquer promising markets!"

Paving slabs from Mikashevichi already adorn the squares of Brest, Luninets, Pinsk, Soligorsk, Mozyr, and other towns across the country, and are gaining popularity in other Russian regions as well. Last year, over 47,000 square meters of space were dedicated to transforming the city for the regional "Dazhynki" festival and fair for rural workers. This year, vibrant, colorful produce was shipped to Beloozersk in the Berezovsky District, which has taken over the baton for hosting the main grain harvest festival.

On the banks of the milk river , the Luninetsky Dairy Plant (OAO)

is embarking on a large-scale business plan, "Construction of a Dry Dairy Products Plant," which has received 70 million rubles in credit alone. The company intends to increase its processing capacity from 300 to 500 tons per day. Essentially, a new plant will be built, and to accommodate it, they even had to squeeze out their neighbors—Luninetsky District Agroservice shared a plot of land. On the way to the plant, Pavel Vabishchevich, Deputy Chairman of the Luninets District Executive Committee for Economics, briefed the participants on the project:

Approximately 52% of sales revenue in the district comes from industry. The agricultural sector is represented by 12 agricultural enterprises and 81 farms. These range from small farms with 3-5 hectares of land to large farms with holdings spanning thousands of hectares. The average milk yield per cow is approaching 7,500 kg per year, or more than 300 tons of milk per day. And herd productivity continues to grow—according to the plan for the next five years, at a rate of up to 7% per year.

For example, the Novitskikh farm at its unitary enterprise, Mezhleskoye, already yields 10,000 kg per cow—the highest yield in the district. So, in a few years, it's entirely possible to increase daily milk yield to 400 tons or more. Selling valuable raw materials, including for export, is considered short-sighted, which is why the local dairy has begun a comprehensive overhaul of its drying equipment. The company hopes not only to increase its milk powder production volumes but also to expand its product range.

"The maximum we were able to process this year was 330 tons of raw material per day. That's the ceiling. Furthermore, our two dryers, each with a capacity of 500 kg of evaporated moisture, are quite old and worn out. Renovation was absolutely necessary. A Slovak company won the tender for a drying complex with a capacity of 1,500 kg of evaporated moisture. A designer has also been selected. In addition to increasing volumes, we will be able to produce higher-quality products and new types—this could include whole milk powder and instant milk powder ," the conversation continues in the office of Nikolai Bokhonyuk, the director of the joint-stock company. "We expect to receive our first products in a year and a half, and we will continue to expand production, including whole milk products.

" About 60% of the output of Luninetsky Dairy Plant OJSC is exported—to Russia, Azerbaijan , Uzbekistan , Kazakhstan , Georgia, and Armenia.

The joint-stock company, which at one time acquired two agricultural enterprises, also contributes to milk production . And not only through high milk yields.

"Our specialty is hypoallergenic A2 milk, which we obtain from specially selected cows with two copies of the A2 gene in their DNA. It does not contain A1 betacasein, is as close in composition to human breast milk as possible, and is better digested, especially by young children and the elderly," explains Chief Technologist Natalia Bobkovich. "The introduction of the A2 product line was preceded by extensive and painstaking research. "At our agricultural unitary enterprise, Agro Lobchanskoye, a genetic analysis of the dairy herd was conducted by an independent accredited laboratory, selecting cows with the A2A2 genotype. They are housed and milked separately. Selection continues, including at our second agricultural enterprise, OJSC Sinkevichsky, as well as at one of the district's farms. We produce up to 10 tons of A2 milk per day and supply it to retailers as a premium product in glass bottles under the Asablivae brand. We also use it to make sour cream, butter , cottage cheese , and bio-yogurts with a variety of fillings. Incidentally, our yogurts received three first-place diplomas in the Healthy Nutrition category at the BELAGRO-2024 exhibition.

Natalia's path to the joint-stock company led through Mogilev, where she earned two degrees in technology and economics at the University of Food Science, and Minsk, where, after completing her required two years of work placement at a dairy plant, she followed her husband, radically switching from food production to banking. But in 2019, the family returned to their homeland. Natalia returned to the plant again – because, as the director claims , she is a "God-given technologist."

Alexander Rebkovets, appointed chief engineer six months ago, is equally involved in the new project. His team will be responsible for the project's approval and equipment installation. A plus is that he knows a working dryer inside and out – he began his career at the dairy plant, practically straight out of school: he worked as a mechanic during his internship at the Pinsk State Agrarian Technological College and then spent several more years working placements. Alexander lured his wife, Olga, from Brest to Luninets. He met her during his first year of college and soon discovered that they were both born on November 17, 1984.

"I'm 12 hours older," Alexander smiles, having since become very skeptical of the veracity of horoscopes. "We're not very similar in personality. But somehow we learned to overcome difficulties. We even built a house ourselves, between picnics on the property."

Like many (in fact, the vast majority of families in the Luninets region), the Rebkovtsys' hobby is growing strawberries on their plots of land in the village. The income from hard labor on the land in their spare time is a good supplement to their salary. But now, says Alexander, there's hardly enough time for that—all his attention is on the new production project, on which the future of the company depends.

24 years on the runway

On the day of our arrival in the Luninets district, near its border with Soligorsk, an important event was taking place at the Novitskikh farm. Incidentally, this is the same farm where they milk 10 tons per cow annually, providing a reliable raw material base, including for the local dairy plant. A second automated vegetable blast freezing line with a capacity of 10 tons per hour was being commissioned, marking the completion of a two-year, €7 million project. Of course, we couldn't miss it.

Especially since this farm doesn't fit the usual clichés. It's simply gigantic. Judge for yourself. They lease 9,000 hectares of land. They employ more workers than any of the other farms we visited – around 500, including the acquired Mezhleskoye UP, which hasn't changed its specialization and continues to farm livestock, raising 4,000 cows.

In workshops spread over 10 hectares, potatoes , carrots , and beets are washed and packaged in special breathable packaging or, if necessary, chopped and frozen. A deep-freeze plant for vegetables and berries has been built using state-of-the-art freon-free equipment.

The farm was one of the first in the country to begin packaging washed vegetables 12 years ago. To effectively preserve fresh vegetables during the off-season, it uses state-of-the-art storage facilities with a capacity of 80,000 tons.

Add to this 55 of its own trucks, equipped with temperature recorders and loggers to monitor temperature and humidity en route, ready to deliver vegetables anywhere in the country within 48 hours for orders of 20 tons or more. And not only that.

Last year, 100,000 tons, or 90% of the harvest, was exported. This year, these figures are expected to increase. Because they grew 6.5 times more carrots than the entire country allocates to stabilization funds during the off-season, and if necessary, they could fill the entire country's granaries with potatoes. The main export market is Russia . They export carrots, potatoes, and beets there, which have been grown for the past five years using a new and effective precision farming technology.

Vladimir Novitsky, born in the Luninets region to a large family, started the business 24 years ago with an old tractor and 50 hectares of rented land. His father worked as a driver, his mother as a field worker. And his son took up growing carrots on the site of a former runway, from which crop duster planes once took off to spread fertilizer on the fields. Vladimir Konstantinovich's business took off brilliantly. Today, many of the head of the farm's relatives are involved in the production process, and his children , including the youngest, also help out.

"Everything in our team is built on trust and personal example. How else could it be?" the owner greets us with a smile and gives us a personal tour of the enormous workshop where vegetable production is in full swing, as well as the storage facilities where it's easy to get lost without a guide. "This year's potato harvest is good, and the carrot harvest is simply excellent: we harvested 300 and 800 centners per hectare, respectively. We primarily fulfill retail orders. We sell potatoes domestically for 68 kopecks per kg, and a little more expensive abroad – 80 kopecks. Stabilization funds have been fully formed.

The head of the farm is confident that there will definitely be plenty of vegetables in the country."

In numbers:

According to Belstat, the contribution of agricultural production to Belarus's GDP in 2024 exceeded 6%. Per capita, the country produces 913 kg of grain, 958 kg of milk, 41 kg of potatoes, and 304 kg of vegetables. Agricultural organizations account for 78.9% of output, peasant farms account for 2.9%, and the remaining 18.2% is grown on private plots.

Protecting the Lives of Rescuers:

The unique Republican Production Unitary Enterprise "Uniform," part of the Bellegprom concern, will celebrate its 25th anniversary next year. Uniform develops, manufactures, and mass-produces firefighting gear, including special protection against extreme heat—it can withstand temperatures up to 600 degrees Celsius. And not only that. We mistook the suit worn by rescuers who deal with stinging insects, usually hornet infestations, for beekeeper gear. We were surprised to learn that a hornet flying at up to 15 meters per second can easily knock a person off their feet.

"We are the main supplier of protective suits, gloves, gauntlets, and helmets for the Ministry of Emergency Situations. We produce clothing with special protective properties that meet international regulations," says Director Irina Senyuk, greeting us in an office adorned with certificates of appreciation from the Ministry of Emergency Situations. "There is demand for our products not only domestically but also internationally."

To confirm the director's words, we notice Arabic script on the protective jackets being sewn in the workshop. Irina Nikolaevna, noticing the surprised looks, immediately comments:

"We are currently making suits for rescuers from Libya. A delegation from there visited us this summer and learned about the production process. We ordered 60 sets of suits with helmets and gloves for competitions—this is a joint project with our Ministry of Emergency Situations. The entire contract is for 400 sets. We use a rubberized material, and the suits, helmets, and gloves are the same as those worn by our rescuers." All materials are domestically produced, with the exception of reflective hot-melt tape.

Uniform exports 11% of its output, but only because it can't fulfill domestic orders due to insufficient production capacity. "

We're planning to expand. We expect to double production volumes by 2028. We'll be building a 32-person workshop in Luninets, primarily for seamstresses. Our Mikashevichi facility will remain the developer and holder of all documentation and certificates. We conduct compliance testing at the Fire Safety Research Institute and the Vitebsk Scientific and Practical Center of the Ministry of Emergency Situations, and we closely collaborate with the Republican Emergency Management and Response Center of the Ministry of Emergency Situations on material properties," the company's director continued, demonstrating the latest product. "

Yes, don't be surprised—rescue suit designs are also constantly being improved and changed." For example, today, the Ministry of Emergency Situations (MES) staff consider a more convenient option: a separate jacket and coverall, all secured with metal latches. This works well in extreme situations, for example, if a tank is on fire and there's a risk of an explosion and a blaze, a firefighter who enters and contains it will be easier to evacuate via a hitch.

"Even though everyone thinks it's a cosmonaut suit," the interviewee smiles. "The suit can withstand temperatures of 600 degrees Celsius, the metallized coating is Chinese, and the fiberglass is domestic. The materials are combined in Vitebsk, bonded with a special fire-resistant adhesive. The helmets are also manufactured using molds developed as part of a joint research project with the Research Institute of Fire Safety and Emergencies of the Ministry of Emergency Situations. All rights reserved. We do the assembly, interior fittings, and testing ourselves.

We're considering another version of the "cosmonaut suit," which turns out to be an export version—designed for Russian firefighters and certified according to the GOST standards of the Union State. Incidentally, Russians prefer overalls without a separate jacket.

The construction of a new workshop in Luninets is intended to expand supplies to Russia. Additional jobs will be created for residents of the region, and we'll bid farewell on this positive note, but we'll return to see how these plans come to fruition. It's important that they continue to stimulate the forward movement that continues in the Luninets region. It's proven.

From the horse's mouth

, Alexander Savin, Chairman of the Luninets District Executive Committee,

says , "Our district is industrial and agricultural. The main industrial giant is RUPP Granit, with a processing capacity of 300 tons of crushed stone per hour and a share of up to 50% of industrial output, employing 2,106 people."

Small businesses are also completing the five-year plan with flying colors, demonstrating growth of 1.3-1.5 times. These include the dairy plant, recognized as the best in the district last year, Spetszhelezobeton, and Viktoria, the only manufacturer of cast aluminum cookware with a non-stick coating in the country, producing up to 100,000 frying pans per month. The husband and wife team started the business , figuratively speaking, in their garage. Today, they employ 238 people. Their products are in demand both domestically and internationally.

All our agricultural enterprises are profitable, and the number of farmers is growing every year due to the consolidation of their private plots. However, land is not as scarce here as in other districts. Farmland located near the M10 highway has long been taken up. Farmsteads within a 20-30-kilometer radius are not cheap. Large farmers primarily cultivate vegetables, while smaller ones focus on strawberries, blueberries, and raspberries.