In Bashkortostan, a meat semi-finished products plant increased production by 16% thanks to the national project "Labor Productivity"

- Participation in the national project "Labor Productivity", firstly, gives enterprises the opportunity to identify problems using analysis and diagnostic tools. And, secondly, with the support of RCC experts, to solve them, - noted the First Deputy Minister of Economic Development and Investment Policy of the Republic of Bashkortostan Airat Fakhretdinov.

The changes were introduced in the flow from receiving raw materials to assembling finished products. The perimeter of the pilot site included: raw material warehouse, boning, spice preparation site, vegetable preparation site, cutter shop, minced meat shop, dough preparation site, molding and packaging site. About 16 problems were identified there, for which the enterprise's working group, together with RCC expert Elnar Sirazetdinov, developed an action plan to achieve target indicators.

Thus, the following decisions were made to optimize the flow:

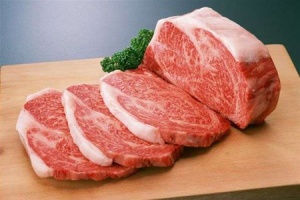

- use chilled meat instead of frozen, due to which they were able to save 27 hours and, accordingly, free up additional space in refrigerators and eliminate the operation of defrosting raw materials;

- redesign the minced meat shop, dividing the zones into "Baked Goods", "Dumplings" and "Cutlets";

- develop a standard for minced meat preparation, in which timers were installed to track time , and a standard for accepting meat from the supplier;

- reorganize the packer's workplace, and in general, apply the "5S System" to organize work zones and storage areas;

- launch an automatic packing line.

One of the key decisions was to balance the work of the molders and the shock freezers to eliminate under-freezing of finished products.

All these measures allowed to reduce the process time by 32% (from 94.7 hours to 63.6 hours) and reduce work in progress by more than 7% (19,979.2 kg to 18,872.2 kg).

- The enterprise's working group actively worked within the framework of the national project. The employees were trained in 7 basic trainings, visited the model enterprise of JSC "Pishcheprom" (Buzdyak village). Now they will replicate the experience they have gained independently. To further improve the flow of pelmeni, it was proposed to move the packaging machine and organize a separate warehouse for pelmeni near the shock freezing, - said Elnar Sirazetdinov.

Let us recall that the plant is located in Davlekanovo. The manufacturer's portfolio includes two brands: "Dobrynin" and "Davlekanovsky Plant of Meat Semi-Finished Products". The assortment includes more than 80 product names: pelmeni, vareniki, pastries, meat semi-finished products.