HM Series Rotary Homogenizers

Homogenizers of this type are suitable for preparing samples before further analysis, emulsifying food, paint and chemical products: dairy products, juices, vinegar, fat, molasses, etc. They have a very high efficiency. During operation, the homogenizer creates a flow that moves vertically and enters the working element from below. After passing and moving upward through the workpiece, the flow meets the height-adjustable baffle and changes the direction of movement to horizontal, thus ensuring effective mixing and consistent entrainment of the entire volume of substance into the workpiece. The absence of settling and separation ensures not only high emulsification quality but also the mixing of the phases. The vertical position of the baffle plate is adjustable with a special rod and can be adjusted even during operation.

For the preparation of samples of dairy products, dairy compounds and milk products, as well as yoghurt, usually used rotary homogenizer with a four-blade knife HM-312, which can work with containers with a capacity from 100 to 2000 ml (for the preparation of samples in accordance with GOST usually used laboratory beakers from 200 to 1000cc, and for the preparation of dairy products the containers of 1.0 cubic dm). For sample preparation, the angular speed of the blades is set between 1,000 and 10,000 rpm. The homogenization of samples is performed in standard laboratory beakers or other vessels into which the homogenizer operating element is immersed. The rotational speed is set on the control panel of the instrument. The precisely manufactured high-speed rotor creates a distinct pumping effect during the suction of liquid into the inlet opening of the stator. At high speed, the liquid flows through the stator outlets. This combination creates high mechanical and hydraulic shearing forces in the product. Many processes, such as emulsifying and dispersing pigments and dyes, as well as other solids in liquids require high shear torque. Our rotary homogenizers presented on this page are designed for laboratory and pilot plants for processing volumes from 0,1 to 20 liters. Our company offers an industrial series of rotary homogenizers for volumes up to 1500 liters.

Series HMB is equipped with brushless motor, other models of HM series are equipped with high-speed DC motors with high service life (AC to DC converter is inside the body and is part of the control system). All HM series homogenizers are supplied with standard AC 220 V, 50 Hz.

All HM series homogenizers are supplied with a rack equipped with a spring elevator and base. Spring elevator makes it much easier to work with the device because when you change the height of the homogenizer the weight of the drive is compensated by the built-in spring. The basic package includes all necessary accessories.

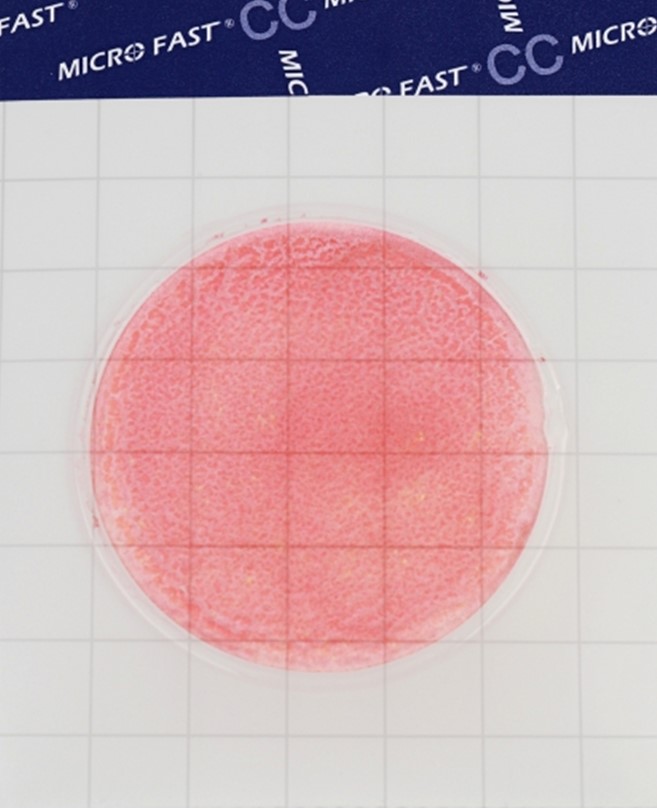

Homogenizers SS series have a special design of the emulsion head. Small round-shaped holes located along the diameter of the stator ensure the best mixing of solids in liquids to create homogeneous suspensions.

Features and Benefits:

Spring-loaded lifting mechanism for easy operation.

Automatic torque boost for constant speed.

Overheat protection, fuse.

High speed and torque stability.

Infinitely variable speed control.

Homogenization block in AISI 316 stainless steel.

Faster mixing compared to other types of devices.

High homogeneity of the product.

Fine pulverization of suspended solids and emulsion droplets.

Fast wetting and dissolution of powders.

Small gap between rotor and stator for high shear force.

Read together with it:

- From exports to skills exchange: What do Belarusian and Tatarstan farmers see as the potential for partnership?Photo by the Ministry of Agriculture and Food, January 19, Minsk . Minister of Agriculture and Food of Belarus Yuri Gorlov discussed the further development of cooperation at a meeting with Deputy Prime Minister of the Republic of Tatarstan - Minister of Agriculture and Food Marat Zyabbarov. The ministry's press service provided details of the meeting to BELTA. The parties exchanged agricultural e...

- Cuba: Key facts about the country and why Trump is interested in itHavana, Cuba Content: Where is Cuba located? Cuba as a state Economy of Cuba Why Cuba is important to the United States Donald Trump's Interest in Cuba US sanctions against Cuba Protests in Cuba Changes in Cuban society Where is Cuba 00:00 Advertisement 00:00 00:00 / 02:03 You can skip the advertisement in More detailsCuba is an island nation in the Caribbean between North and South America. Situa...

- China cuts tariffs on EU pork imports after lengthy investigationChina has significantly cut tariffs on pork imports from the European Union, providing partial relief to European producers after an 18-month anti-dumping investigation that was widely seen as retaliation for EU duties on Chinese electric vehicles. In its final decision published on Tuesday, China's Ministry of Commerce set new tariffs ranging from 4.9% to 19.8% on EU pork imports for a five-year ...

- Рост оптовых цен в Германии: ноябрь 2025 годаОсновные факторы роста Главным катализатором роста оптовых цен стали продукты питания, напитки и табачные изделия, которые подорожали на 3,2%. В частности, наиболее заметно увеличились цены на кофе, чай, какао и специи, которые подскочили почти на 22%. Это связано с несколькими факторами, включая неблагоприятные климатические условия в странах-производителях, что приводит к снижению урожайности, а...

- Analysis of food price changes in Russia: latest data as of December 8, 2025Key findings: Changes this week: Prices for 25 products increased, 16 decreased, and one remained unchanged. The average increase was 0.01%. Changes for the month: Over the month, prices increased for 29 items and decreased for 13. The overall increase was 0.8%. Annual dynamics: Over the year, prices increased for 28 goods and decreased for 14, which averaged 2.......

- Лечение рака в пробирке, недорогие аккумуляторы. Над какими проектами работают белорусские ученыеНа недавнем совещании по вопросам развития научной сферы и деятельности Национальной академии наук Беларуси глава государства в качестве принципиальной задачи обозначил устранение разрыва между лабораторными разработками и потребностями реального сектора. Президент отметил, что наука в ближайшую пятилетку должна стать настоящим драйвером развития страны. Речь о практикоориентированности научных ис...