Next-Generation Artificial Meat: Metamaterials in Action

Recent research conducted by scientists from the Hebrew University of Jerusalem opens up new horizons in the production of artificial meat. For the first time in the world, metamaterials have been used to create whole artificial steaks, which represents a significant step forward in the field of food technology. This work was published in the prestigious journal Nature Communications and has already attracted the attention of both the scientific community and the general public.

What are metamaterials?

Metamaterials are unique composite materials whose properties do not depend only on their chemical composition, but also on their structure. This means that by changing the architecture of the material at the micro- and nanoscale, scientists can achieve desired characteristics such as strength, flexibility and even the ability to change optical properties. In this case, applying principles commonly used in the aerospace and defense industries, the team led by Dr. Muhammad Ghosheh and Professor Yaacov Nahmias was able to create artificial meat that imitates the complex structure of muscle and fat.

New Manufacturing Technologies

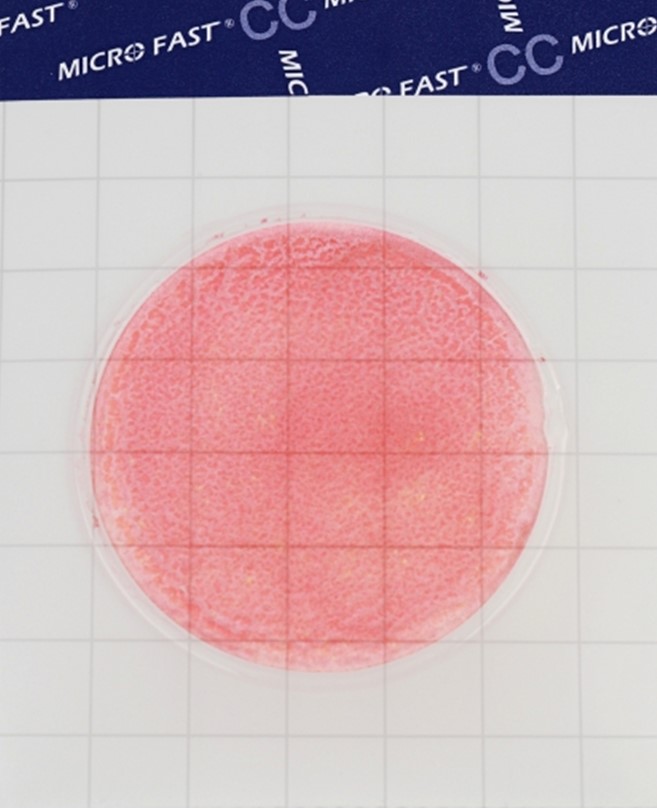

The development of artificial meat using metamaterials involves the creation of two new types of materials: low-temperature meat analogue (LTMA) and proteoleogel (PtoG). LTMA reproduces the fibrous texture of muscle tissue, making it ideal for creating steaks and chops. Proteoleogel, in turn, is an oil gel stabilized by plant proteins that imitates the structural integrity and properties of animal fat during heat treatment.

The method used to produce these materials is based on injection molding, a high-performance process that has long been used in the polymer industry. This allows for a significant acceleration of the process of creating artificial meat and increases its availability on the market.

Advantages and Prospects

One of the key advantages of using injection molding is the ability to scale up production. Unlike slow 3D printing methods, which often limit mass production, injection molding allows for a significant reduction in the cost per kilogram of artificial meat - up to $ 9. This opens the door to a wide range of consumers and may change the perception of meat products in the future.

With growing interest in sustainable food sources and the environmental issues associated with traditional animal agriculture, cultured meat created using metamaterials could be an important step towards a more sustainable future. Not only will it reduce the burden on the environment, but it will also provide access to quality food for the world's growing population

.Israeli scientists are not just a scientific achievement, but also an important step towards improving the quality of life of people. Artificial meat created using metamaterials can become the basis for a new generation of products that will satisfy the requirements of both consumers and the environment. Many interesting discoveries and innovations in this field lie ahead, and we are eagerly awaiting how new technologies will change the way we perceive food and its production.