"Some solutions are ridiculously simple." Poultry farm "Artemovskaya" was included in the national project among the first

By 2024, the labor productivity of Russian enterprises in the basic non-primary industries should grow by more than 20%. To solve this problem, the state launched a national project of the same name. One of its first participants in the Sverdlovsk region was the Artyomovskaya Poultry Farm.

According to RBC, a pilot project was launched to restart the production of chilled chicken fillet. This is a key product for the company, the most promising product for increasing sales. it provides 19.5% of the company's revenue. At the same time, it is the most resource-intensive in terms of materials and manual labor.

Many Artyomov residents wondered why the products of our local manufacturer cannot be found in chain stores. The answer was simple - it is unprofitable to give "freezing" to large stores at their prices, and "chilled" does not withstand the mandatory requirements for storage due to lack of funds for the modernization of production. Nowadays, such updates cost more than tens of millions of rubles, which the company does not currently have.

In order to improve the situation in the proposed circumstances, to improve the quality and competitiveness of products, the HEAD of the enterprise, Alexei Reshetov, decided to act in a new way.

Moreover, the problem for the leadership of "Curico" has long been known. These are inefficient organization of workplaces, frequent breakdowns of equipment, insufficient productivity and high labor intensity of processes.

After contacting the Regional Competence Center (RCC), a plan for regulating technological processes at the enterprise was developed.

Additional lighting was installed in the workshops and a grinding machine was purchased, thanks to which the output increased by 4%, standardized work was established, and hourly production analysis was introduced.

After that, processing was stopped until 9-10 pm, the MEAT yield in the production of chicken fillet increased by 3%, and the production time was reduced by 52%.

Additional disinfection posts were launched at the production site, and disposable bags were used for product boxes. Temporary storage areas were organized in the workshops, aisles were cleared, and the location of workplaces was changed, which made it possible to reduce the number of employees.

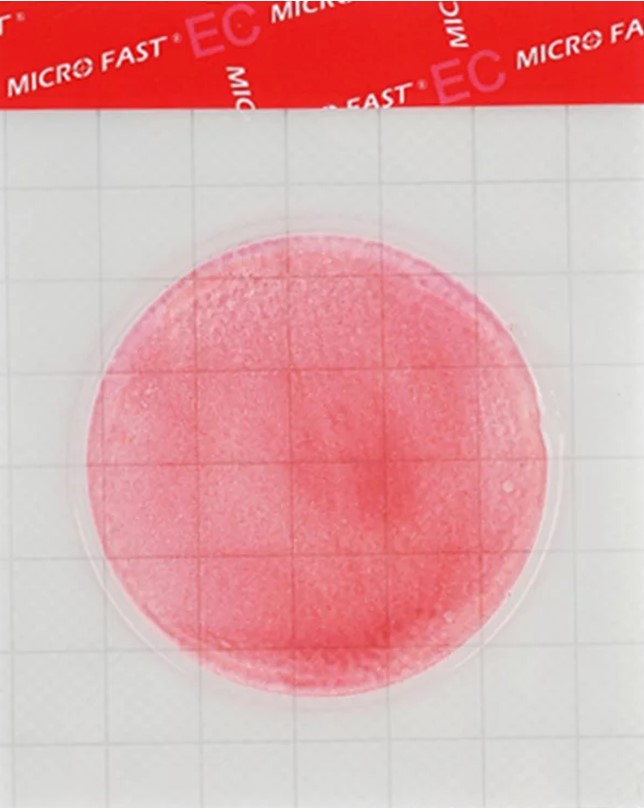

The time spent by products in a warm room was reduced from one and a half hours to fifteen minutes, the shelf life increased from five days to the required seven, and for some items up to ten days - the cases of detecting bacteria on containers stopped. As a result, the percentage of return of unsold fillets by retail chains decreased from 3% to 0.3%. This will save the company 4.5 million rubles a year.

Aleksey Reshetov, General DIRECTOR of the Artemovskaya Poultry Farm:

“At any enterprise there is always room for growth. But it is not always clear how to do it - how to choose the right path that will lead to the result. RCC experts teach to find this way: to analyze the problem and look for a solution using ready-made methods. This is what I liked most about the national project. And I was surprised by how easy it is to achieve savings - just look at the situation from the other side. So, when moving meat between workshops, we traditionally labeled each box - and did not think that one label per pallet with 20 boxes was enough. We calculated and it turned out that reducing the number of labels will save the company 1.5 million rubles a year.”

Used lean manufacturing tools

Mapping

The tool linked together all the indicators of the various workshops. This helped to find a maximum of problems, bottlenecks, losses that hinder production, and develop counter-measures.

Problem Solving Methods The

tool helped to identify the causes of difficulties and find non-standard methods of solving, ultimately raising the quality of products.

5C

Implementation of the 5C system allowed for efficient placement of products in temporary storage areas and cooling chambers. They made workplaces more comfortable, added the necessary little things: knife sharpening machines, lighting lamps, racks for storing inventory.

Alexey Kuvaldin, project manager of the Sverdlovsk RCC:

“For me, the Artyomovskaya Poultry Farm was the first non-industrial enterprise where we helped raise labor productivity. I myself was interested in participating in this project, especially since I am well acquainted with the products of the poultry farm. The specifics of production determined the features of the project: it was necessary to solve other problems than usual, and to use other tools for this. So, the company has already used elements of 5C. Therefore, this tool had to be introduced from the end - from the creation of standards for quality and ease of use. Some solutions have proven to be ridiculously simple but work well, such as using single-use bags in product boxes.”

Results after updates

- output increased by 15%,

- production time decreased by 52%,

- 35% reduction in the volume of work in progress.

So, without further ado and pathos, with the solemn cutting of the red ribbon, the leaders of the new formation are doing their job. Realizing that the well-being of hundreds of Artyomovsk families depends on their decisions, they hold the blows and go forward.

At the time of publication of the material, it became known that on April 21, the general director of the Artemovskaya poultry farm, Alexei Reshetov, was invited to the governor of the Sverdlovsk region, Yevgeny Kuyvashev, for a solemn rewarding of the heads of enterprises that took the most active part in the implementation of the national project "Labor Productivity".

Read together with it:

- The Russian Ministry of Agriculture proposes extending veterinary regulations until 2032.The extension includes regulations for the prevention and eradication of diseases such as bradsot (Clostridium septicum), trichinosis (Trichinella), blackleg (Clostridium chauvoei), and porcine reproductive and respiratory syndrome (PRRS). The proposed changes stipulate the following new deadlines: for bradsot and trichinosis - from March 1, 2......

- UniCredit заявил о галактических усилиях из-за санкций против РоссииUniCredit старается не нарушить «более 15 тыс. санкций», а также не «совершать ошибки», которые позволят изъять его активы в России, заявил гендиректор. После начала военной операции банк начал рассматривать возможность ухода Итальянский банк UniCredit прилагает «галактические усилия», пытаясь соблюсти международные санкции в отношении своего российского подразделения. Об этом заявил генеральный д...

- "Коллективы АПК способны решать любые задачи даже в непростых условиях". Назаров о заслугах сельхозпроизводителейЮрий Назаров 13 ноября, Минск. Обеспечение продовольственной безопасности страны - большое достижение трудовых коллективов аграриев, отметил управляющий делами Президента Республики Беларусь Юрий Назаров на торжественной церемонии награждения государственными и иными наградами работников АПК Управления делами Президента Республики Беларусь, передает корреспондент БЕЛТА. Торжественная церемония наг...

- He crawled to the icon with prayer. The true story of a man who overcame drug addiction.Alexander Ovchinnikov. Topic News. Our project's hero was a drug addict for many years. The thought that this was a dead end never left him, but his addiction proved stronger. One day, when he could no longer walk, he crawled to an icon in prayer. This became his first step toward a new life. Today, he heads a charity center that helps those who have given up hope and are unable to quit ALCOHOL an...

- Колумбия: При экспорте скота сертификация и прослеживаемость больше не являются необязательнымиВысококачественное животноводство, особенно при экспорте, требует сертификации и прослеживаемости. Это необходимые условия для выхода и конкуренции на многих международных рынках, а также на некоторых всё более требовательных внутренних рынках. Колумбийское животноводство не является исключением из этих правил, и, хотя предстоит ещё многое сделать, всё большее число ферм и компаний внедряют эти ме...

- Pharmaceutical companies see a threat to EU security due to bacteria in UkraineAntibiotic-resistant superbugs have been detected in Ukrainian soldiers since the beginning of the conflict, and now they pose a threat to Europe, according to a foundation developing antibiotics.The Ukrainian conflict threatens Europe with antibiotic-resistant "superbugs," said Henry Skinner, CEO of the AMR Action Fund, which specializes in investing in antimicrobials. His article was published o...